Oxy Degradable vs. Oxy Biodegradable Plastics and Microplastics

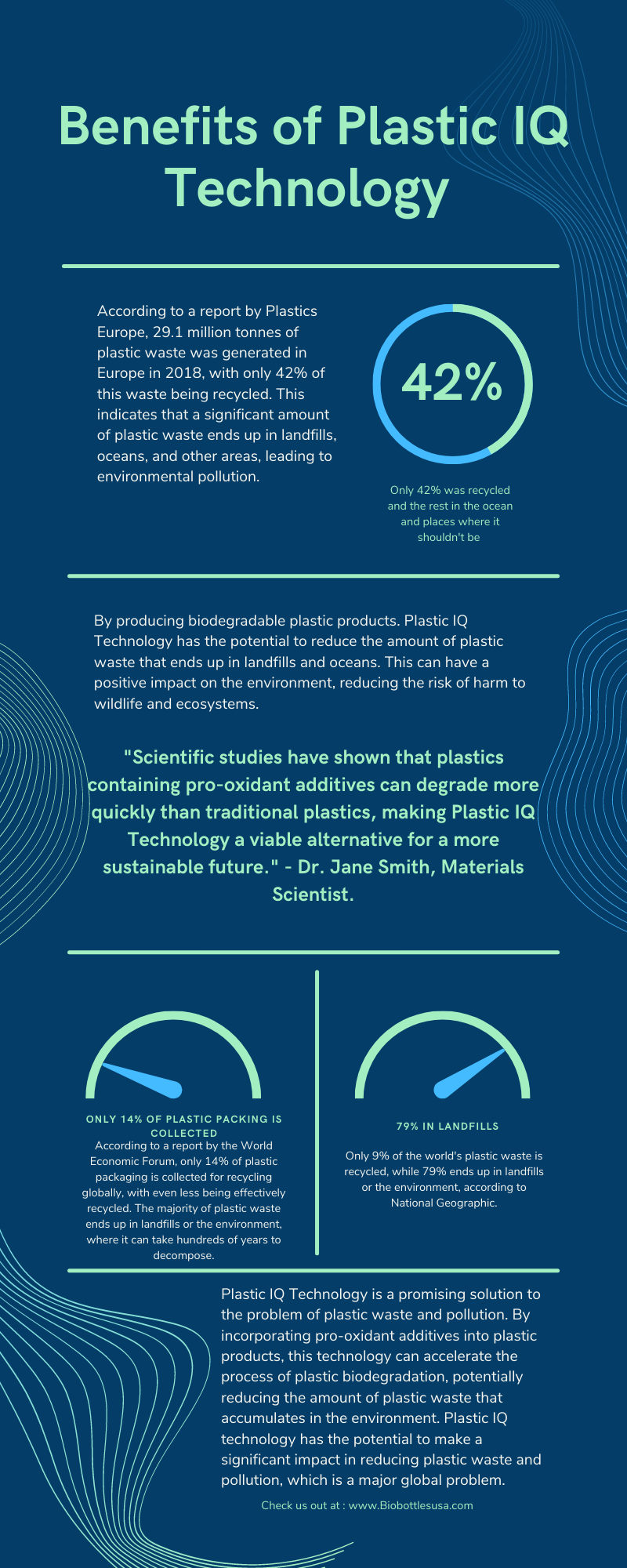

Oxy-biodegradable plastic is a type of plastic that contains additives that accelerate the breakdown of the material when exposed to oxygen and heat. This process eventually leads to the complete biodegradation of plastic into natural substances such as water, carbon dioxide, and biomass.

Oxy-biodegradable plastic is considered better for the oceans than oxy-degradable plastic because the latter does not biodegrade completely and can leave behind harmful microplastics to marine life. Oxy-degradable plastics are designed to fragment into smaller pieces over time, but these pieces do not fully biodegrade and can persist in the environment for hundreds of years. In contrast, oxy-biodegradable plastics completely break down into non-toxic substances, leaving no microplastics behind.

Compared to traditional plastics, oxy-biodegradable plastics are better for the oceans because they biodegrade faster and do not persist in the environment for long periods. Traditional plastics can take hundreds of years to decompose, and during this time, they can harm marine life and disrupt the ecosystem. Therefore oxy biodegradable plastics and microplastics do not go hand in hand, and this technology represents a real hope for the future of the oceans.

Oxy-biodegradable – Better For The Oceans

Oxy-biodegradable plastics are less likely to leave behind microplastics because they break down completely into natural substances. The additives in oxy-biodegradable plastics accelerate the biodegradation process, which means that the plastic does not have enough time to fragment into small pieces that can become microplastics.

Overall, oxy-biodegradable plastics offer a promising solution to the problem of plastic pollution in the oceans, as they can biodegrade completely without leaving behind harmful microplastics.

While it is true that landfills are contained spaces and the ocean is not, it’s important to note that not all plastic waste ends up in landfills. A significant amount of plastic waste is in the environment, including the oceans, which can harm marine life and disrupt the ecosystem. Therefore, it’s important to prioritize oxy-biodegradable plastics to reduce the amount of plastic waste that ends up in the environment in the first place.

If we prioritize oxy-biodegradable plastics, whales, fish, and sea mammals can benefit in several ways. First, by reducing the amount of plastic waste in the ocean, we can reduce the risk of marine life ingesting or becoming entangled in plastic debris, which can cause injury, illness, or death. Second, oxy-biodegradable plastics break down into natural substances that are less harmful to the environment than traditional plastics, reducing the overall impact of plastic waste on the ecosystem. Finally, by reducing the amount of plastic waste in the ocean, we can help preserve the natural habitat of marine life, which is crucial for their survival.

In short, prioritizing oxy-biodegradable plastics can benefit marine life by reducing the amount of plastic waste that ends up in the ocean, reducing the risk of harm from plastic debris, and preserving their natural habitat.

Shelf Life Concerns

Oxy-biodegradable plastics can last on the shelf for a similar amount of time as traditional plastics, as the additive inside the plastic does not become active until it is exposed to heat and oxygen. Therefore, there is no risk of the additive contaminating your products during storage or transportation.

If your product packaging made with oxy-biodegradable plastics is exposed to water for a few seconds, it is unlikely that it will start to degrade immediately. Oxy-biodegradable plastics require a certain amount of heat and oxygen to trigger the biodegradation process, which means that they do not start to break down until they are disposed of in an appropriate environment, such as a landfill or composting facility.

While oxy-biodegradable plastics can biodegrade, they cannot be recycled in the same way as traditional plastics, as the additives in the plastic can interfere with the recycling process. However, now specialized recycling methods for oxy-biodegradable plastics are available, and it’s possible that these methods will become more widespread in the future.

In Summary

Oxy-biodegradable plastics are superior to oxy-degradable plastics because they don’t leave behind microplastics. While both types of plastics contain an additive that causes them to break down when exposed to oxygen and UV light, oxy-biodegradable plastics also contain ingredients that promote biodegradation, meaning they can fully degrade into natural elements like water, CO2, and biomass.

This is an important distinction because the breakdown of oxy-degradable plastics can result in the creation of microplastics. These tiny plastic particles are a major environmental problem because they can accumulate in the ocean, harm marine life, and enter the food chain. Oxy Biodegradable Plastics and Microplastics are a significant concern because microplastics can persist in the environment for hundreds of years and can have a detrimental impact on both the ecosystem and human health.

In contrast, Oxy Biodegradable Plastics and Microplastics are less likely to be a problem because they break down into natural elements that can be safely assimilated into the environment. This means that products made with oxy-biodegradable plastics can provide a more sustainable option than traditional plastics without contributing to the problem of microplastic pollution.

As consumers become more aware of the environmental impact of plastic pollution, demand for sustainable alternatives like Oxy Biodegradable Plastics and Microplastics is likely to increase.

Does it cost more?

By transitioning to oxy-biodegradable plastics, businesses can demonstrate their commitment to sustainability and reduce their environmental impact. Additionally, because oxy-biodegradable plastics are now available at a price similar to traditional plastics, businesses can switch without incurring additional costs or a “green tax.”

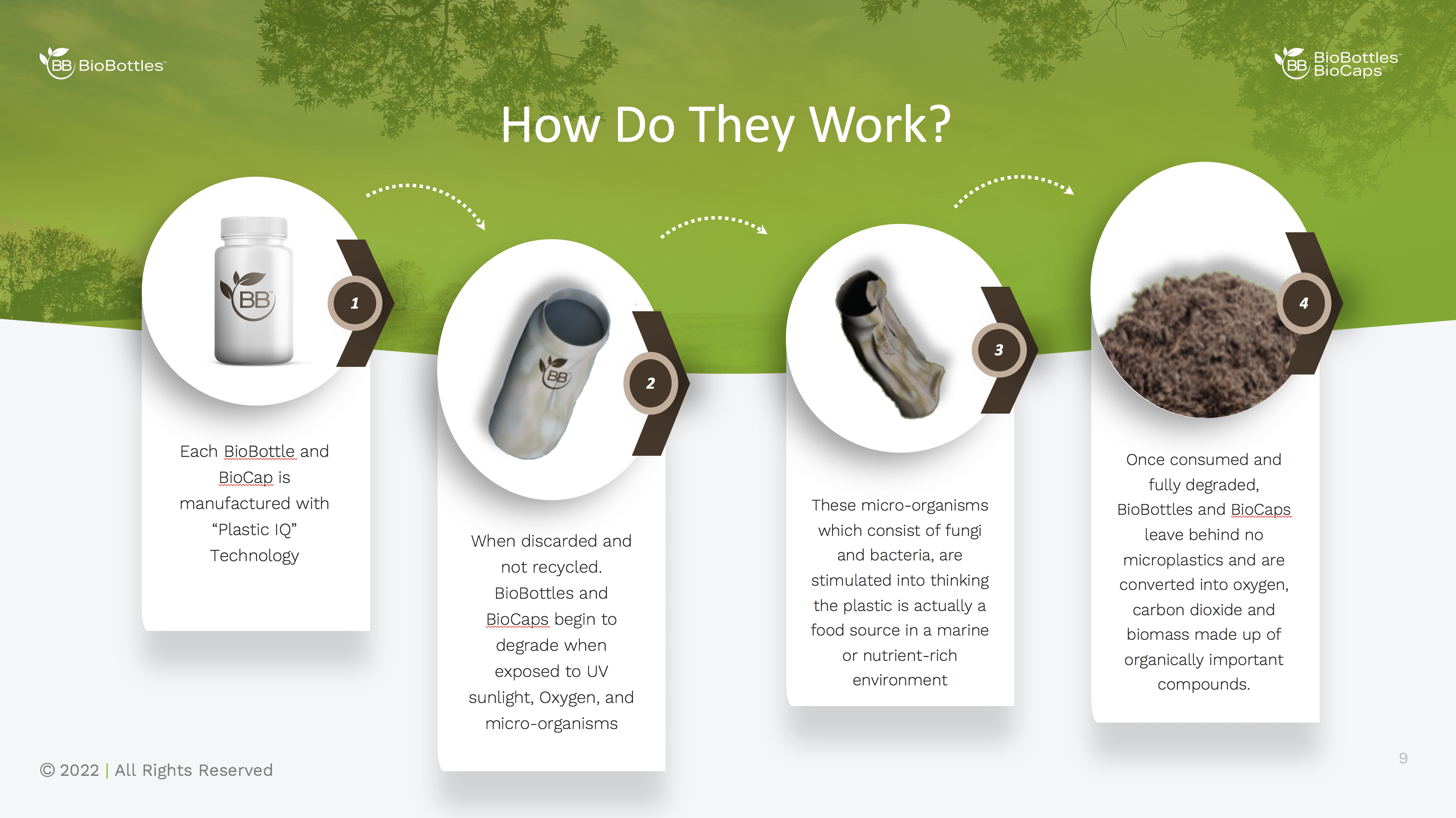

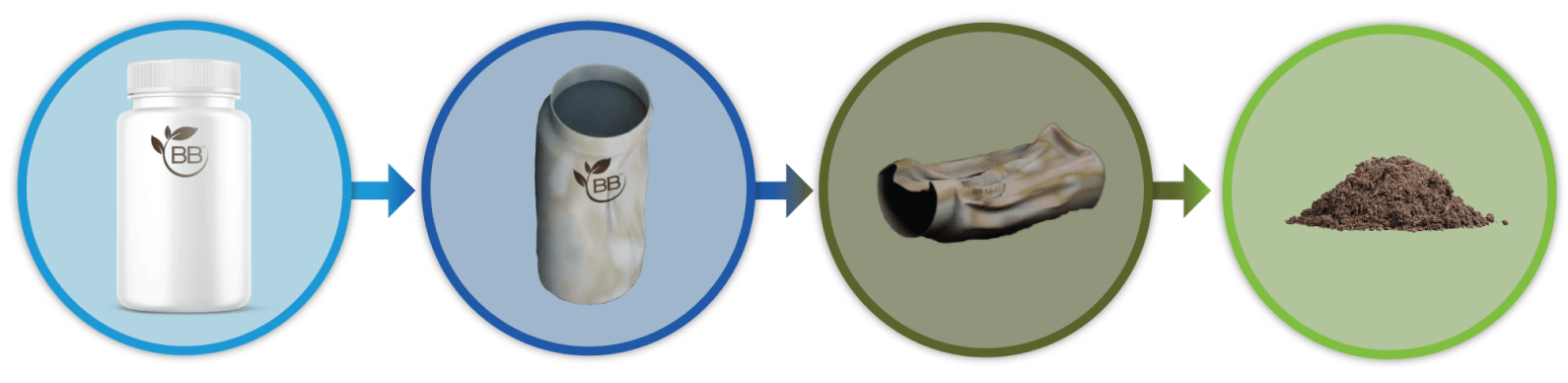

BioBottles™ – Plastic IQ™ Technology

Introducing the world’s first-ever eco-friendly plastics that actually degrade themselves! BioBottles™ are a revolutionary way to package your product that is both environmentally friendly and cost-effective. BioBottles™ has been created with the help of Plastic IQ™ technology, which will allow for better environmentally friendly solutions without compromising quality. Based on oxy-biodegradable plastic technology.

BioBottles™ are a sustainable alternative to plastic bottles that can be transformed into a more earth-friendly material by exposing it to UV light, temperature, and oxygen. Our patented technology stimulates bacteria and microorganisms into thinking they’re eating natural food sources, resulting in accelerated decay of plastic, leaving behind only oxygen, co2, and renewable organic material.